On November 30, 2017, TAKENAKA CORPORATION, which is involved in the construction of various facilities such as commercial buildings, stadiums, schools and educational facilities, etc., built, the "Meguro CENTRAL SQUARE", using our ZERO SCREW™ terminal block EF2 series which was adopted as the main electricity junction for the electric wire in the electrical equipment construction. We interviewed Mr. Shin Tomoyuki, Senior Manager, Mechanical & Electrical Engineering Department, Tokyo Main Office, TAKENAKA CORPORATION.

[Background story] Labor saving at construction sites where it is difficult to secure human resources

TAKENAKA CORPORATION, which is a major construction company engaged in numerous constructions projects, as a corporate philosophy, states they "Contribute to society by passing-on the best works to future generations." including project planning, construction, maintenance and operation of "town“. Throughout the group they are engaged in all life cycles and are developing business to realize a sustainable society.

At the construction site, they are focusing on labor saving, quality control, but also optimum management in terms of process, safety and cost. In recent years they are paying more attention to “labor saving”. “Big events that will be held in Japan in 2020 and large-scale properties since then have also led to a decline in the labor force population, which makes it more difficult to secure workers. It is natural to ensure high quality, and we must actively proceed with labor saving efforts." , said Mr. Shin who is in charge of Construction management at Mechanical & Electrical Engineering Department.

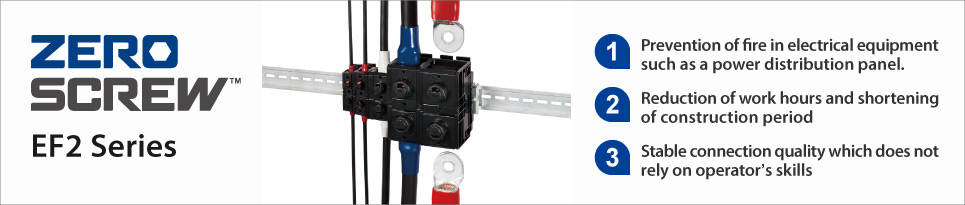

One project that Mr. Shin is in charge is MEGURO CENTRAL SQUARE completed on November 30, 2017. It is a skyscraper office building with 27 floors above ground and 2 underground floors, and is attracting attention as a new landmark along with two housing buildings. The ZERO SCREW™ terminal block EF2 series (hereinafter EF2) developed by HIROSE was adopted for labor saving at this construction site.

[Selection point] As a main electrical junction, it is easy to restore the original state when tenants relocate

Mr. Shin was actively working on labor savings and was introduced to the EF2 by the quality control section equipment department. "Initially it was introduced as a terminal block to be used in the distribution board, but when I looked at EF2, I imagined it could be used for the connection to the main electricity", Mr. Shin said. Normally, in the electrical facility construction that supplies electricity to tenants, the main electricity extends to the distribution board installed on the floor, from which electricity is supplied to each facility in the tenant. However, since the main electricity itself is owned by the building owner, it is necessary to restore the original state when changing the tenant. Sometimes it takes 10 people to pull around cables longer than 100m by hand.

"Using the EF2, you only need to wire the joint part according to the tenant's request, restoring the original state does not take time. In actual connection, you can connect by inserting without using a special tool, just look at the main body to see if it was plugged in. No need for torque management. I believed that we can achieve both quality assurance and labor saving.

However, at first, we had anxiety about the connection by simply plugging into the EF2. "In traditional construction, screw tightening is done at the optimum pressure using a dedicated wrench, and the numerical value of this torque management was an index of quality control. While it is clear that just plugging in the EF2 leads to labor saving, there was no management indicator like the torque value. Therefore, a voice of anxiety occurred from the work site", said Mr. Shin.

So, "I tried the EF2 samples at the work site and asked the workers to confirm the equivalent torque value data presented by Hirose. We confirmed safety with a temporary power supply and gained understanding by stakeholders including the on site workers".

[Operation and evaluation] Provide value to both owners and tenants. Contribute to improvement of management efficiency

Today, the EF2 is introduced at MEGURO CENTRAL SQUARE's tenant space, as a main electricity junction for supplying electricity to 28 stores in triples multiply by 2, and within the distribution board of the office tenant. Mr. Shin evaluates that the main electrical joints are made more concise compared with the conventional method which required skilled work. "If there is a problem in construction, for example, weak crimping, would lower the insulation resistance and it may lead to electrical leakage. Therefore, it was common that experts built the joints with their own special tools and a young man supported it. In fact, while skilled workers would do it, the EF2 will be connected by simple, so work efficiency has definitely improved.

In terms of labor saving, Mr. Shin evaluates that "In the past, it took nearly 3 hours per line, but now it takes only 1 hour by using the EF2." Continuing to reduce labor is critical and it is part of the whole construction project. It leads to improved workability and labor saving. Of course, it is easy to restore the original state when tenant changes. It also leads to cost savings, which will be beneficial to both the owner and the building tenant.

In terms of quality control, "A certain quality is secured by the connector at the factory. The insertion state can be visually confirmed and the torque management is unnecessary, so even without special maintenance, quality is ensured" said Mr. Shin.

[In the future] Accelerate "Connectorization" at the construction site with Hirose

In the future, Mr. Shin would like to utilize a connector not only at the main electrical junction, but also at various parts of the construction site. Connectorization includes a certain level of quality secured at the factory, thereby preventing human errors and labor saving at the work site. According to the company’s data, 30% reduction in working hours has already shown as a result of the connectorization of lighting. With this, there is also a possibility that connectorization will be advanced in every part of the construction site. "In fact, TAKENAKA CORPORATION has co-developed a connectorization of lighting with Hirose.

Mr. Shin hopes that Hirose will actively visit the construction site and make new connector proposals after viewing the site from a different viewpoint from the conventional construction industry. "We are just beginning to take the first step in connectorization in the construction industry and we would welcome proposals for improving the site as a partner who will join our future.

(Interviewed in March, 2018)

Copyright© 2018 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

Hirose Electric Co., Ltd. and ZERO SCREW (TM) are trademarks or registered trademarks of Hirose Electric Co., Ltd. Other company names and product names are registered trademarks of respective companies. The position stated in the case example is at the time of interview.