Ideal for Use in Electrical Power Applications Including Power Distribution Panel

ZERO SCREW™ Terminal Block EF2 Series

Prevent Fires in the Power Distribution Panel By Eliminating Screws

Shorten Construction Time

The ZERO SCREW™ Terminal Block EF2 Series is a spring terminal block that can connect cables to electrical equipment such as power distribution in buildings without using screws. Eliminating screws saves installation works and maintenance time. In addition, EF2 prevents accidental fires triggered by the loosening of screws in electrical power applications.

ZERO SCREW™ Digital Catalog

>View this E-book in full screen

Prevent Fires in Electrical Equipment Including the Power Distribution Panel

An electrical fire not only endangers the life of building users, it also lowers trust in developers, construction companies and fire source product suppliers. About 70% of the cause of electrical fires is poor handling and lack of maintenance. More specifically, screw looseness can be identified as the cause of these fires. Period maintenance and inspection of screws is required. Even with periodic maintenance, it is difficult to completely prevent an accident.

The ZERO SCREW terminal block maintains a highly reliable connection for a long time with its unique, screw-less design that reduces fire risk caused by loose screws in electrical equipment to zero.

Reduced Work Hours and Shortened Construction Period

With screw type terminal blocks, screwing and unscrewing is required for new construction and torque checking is needed during maintenance. Since the ZERO SCREW Terminal Block has no screws, it can reduce the number of work hours by more than one-third compared to a conventional screw terminal block for a dramatic reduction in construction time.

Stable Connection Quality Regardless of Operator Skill

During electrical equipment maintenance, EF2 streamlines the installation quality since there is no variation from inexperienced operators failing to tighten the screws or do torque control. A stable connection is maintained regardless of the operator.

Introduction example

Simplifying the construction process

KAJIMA CORPORATION, which builds skyscrapers, shopping centers, dams and bridges with civil engineering technology, implements environmental conservation efforts and earthquake disaster countermeasure technology into their construction. In order to save labor resources and attract new workers, Kajima Corporation began use of Hirose’s Zero Screw™ terminal block EF2 Series. The deputy director of the Tokyo Building branch, Mr. Hiroshi Mizui, describes the effects of implementing this connector. (Published January 10, 2019)

Utilization as a new main electricity junction, changes the construction process.

On November 30, 2017, TAKENAKA CORPORATION, which is involved in the construction of various facilities such as commercial buildings, stadiums, schools and educational facilities, etc., built, the "Meguro CENTRAL SQUARE", using our ZERO SCREW™ terminal block EF2 Series which was adopted as the main electricity junction for the electric wire in the electrical equipment construction. We interviewed Mr. Shin Tomoyuki, Senior Manager, Mechanical & Electrical Engineering Department, Tokyo Main Office, TAKENAKA CORPORATION. (Published July 23, 2018)

ZERO SCREW™ Terminal Block EF2 Series Features

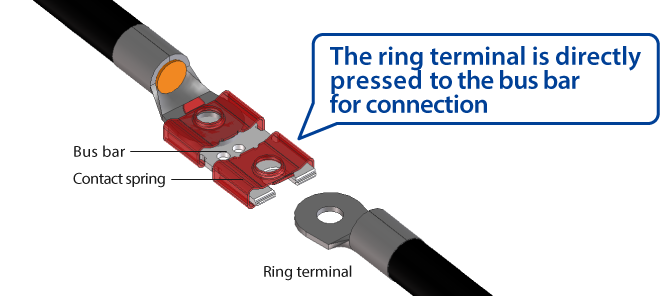

Easy Connection with Standard Ring Terminal

Quick and secure single action positive lock design. Unlike a conventional screw terminal block, the operator can maintain stable work quality even if they are not a licensed electrical engineer. In addition, it is easy to use in narrow and dimly lit places.

Enhanced Contact Reliability

Unique design for pressing the ring terminal directly against the bus bar for connection. Contact reliability is improved and a stable connection is maintained over a long-term.

Wiring Work Video

Installation method

Wiring in the board

Lead-in external lines

Work hours comparison

Application Example

Solar power generation equipment

Product lineup EF2 Series

| Series | Applicable Cable/ Rated Current |

Rated Voltage | Operating Temperature | Storage Temperature | Contact Resistance | Insulation Resistance | Withstanding Voltage | Mating Durability |

|---|---|---|---|---|---|---|---|---|

| D30 | 1.25mm2=16A 2mm2=21A 3.5mm2=30A 5.5mm2=40A |

600V AC/DC |

-25 to +105℃ (Includes the temperature rise due to current flow.) |

-10 to +60℃ | 1mΩ Max. (1A DC) |

1000MΩ Min. (500V DC) |

2500V AC for 1 min. | 50 times |

| D60 | 5.5mm2=40A 8mm2=50A 14mm2=70A |

|||||||

| D150 | 22mm2=94A 38mm2=132A 60mm2=175A |

0.1mΩ Max. (1A DC) |

||||||

| D200 | 60mm2=175A 100mm2=240A |

1000V AC, 1500V DC |

5000V AC for 1 min. | |||||

| D250 | 150mm2=310A | |||||||

| D400 | 200mm2=400A | |||||||

| D500 | 250mm2=500A |