KAJIMA CORPORATION, which builds skyscrapers, shopping centers, dams and bridges with civil engineering technology, implements environmental conservation efforts and earthquake disaster countermeasure technology into their construction. In order to save labor resources and attract new workers, Kajima Corporation began use of Hirose’s Zero Screw™ terminal block EF2 series. The deputy director of the Tokyo Building branch, Mr. Hiroshi Mizui, describes the effects of implementing this connector.

[Background story] Seeking a simple worksite environment

Founded in 1840, Kajima Corporation’s company motto is “a vision for all eras”. Through high-level technology, KAJIMA CORPORATION operates as a super general contractor, undertaking a wide array of construction and civil engineering projects, including the building of skyscrapers, railways, dams, and bridges, offices, schools and medical centers.

Beginning in 2000, KAJIMA CORPORATION began to improve the efficiency of the construction process by accelerating technology development in order to secure more employees. ‟We developed a more efficient construction framework in order to assure the quality of our products and handle the decrease in worker population that has resulted from the declining birthrate and aging population,” Mr. Mizui states.

One of the goals of this framework was to enhance the efficiency of apartment construction by improving the connection of distribution boards. ‟Since distribution board area is kept to a minimum in the shared apartment spaces, it takes time to connect within a narrow shaft. By establishing the distribution board’s connection at the factory beforehand, we found that only on-site connectors were needed to generate a union.” Mr. Mizui aimed to expand the concept of simplicity to following projects by actively attending exhibitions in a search for new technologies applicable to electronic construction.

[Selection point] Using existing Terminal Lugs without needing to retighten screws

![[Selection point] Using existing Terminal Lugs without needing to retighten screws](https://prd-4s-public.s3.amazonaws.com/product/en/pr/case/img/case_02_04.jpg)

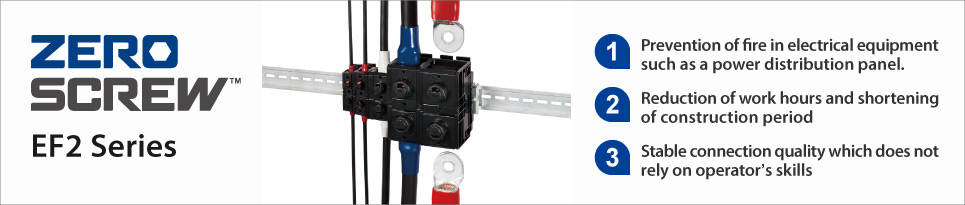

During that time they discovered the Hirose ZERO SCREW™ terminal block EF2 series (hereinafter EF2). “At that time I was in charge of the Facility Construction Division for the Tokyo Civil Engineering rebuilding project (hereinafter KT building). This was an internal project and I was given the opportunity to propose the use of new production technology. The product I found while attending exhibitions was the Hirose EF2 series. I thought we could improve construction efficiency by using a spring to create the electrical connection from screw to connector. For that reason I was really interested in trying the ZERO SCREW™ series.” This project was the perfect opportunity to implement the newest technology with a new connector.

When Mr. Mizui first saw the EF2 series, he was impressed by how generic terminal lugs used in electrical construction could be easily inserted. “Workers feel hesitant using a specially shaped crimp terminal that requires maintenance and other safety precautions. If there is a terminal lug that can be used with general terminal lugs workers are familiar with that does not have these requirements, then even experienced electricians will happily adopt it.”

Mr. Mizui also spoke on the value of not needing to retighten screws. “The EF2 series can hold down the round clamp since constant pressure is applied to the terminal lug by the springs. For screw tightening torque management is not necessary and the spring lasts for 35 years. It is safe to use because product quality is guaranteed.”

After two years without safety or operation issues in the KT building and other small projects that were completed with the EF2 series, Mr. Mizui began expanding the use of EF2 into newer, large-scale projects.

[Operation and evaluation] Only plug insertion is needed at the work site. Simplifying the construction process

After introducing the EF2 into multiple buildings, including the KT building, Mr. Mizui talked to the building owners about the maintenance effectiveness of EF2. As a result the building owners decided to adopt it for receiving transformer equipment, distribution panels and power boards. The EF2 series is used in the power line on both the primary and secondary side of the power route, from the cubicle (receiving and transforming equipment) to the distribution board and switchboard. On the primary side alone the EF2 is applied over 400 times.

In using the EF2 Mr. Mizui expects to simplify the connection process. In general, after connecting the power line, the terminal is tightened before energizing. Then the electricity is turned on in the trial operation. Lastly the terminal is retightened and then the process is completed. “When electricity is running, heat is generated and springs can loosen. To prevent accidents retightening is performed several times. However the EF2 secures the terminal with pressure so that loosening does not occur and retightening is no longer needed,” Mr. Mizui explains.

Cable assembly occurs at the panel factory. In doing so, this step is no longer required on the worksite. As a result end waste material is eliminated and the only action needed at the construction site is inserting the terminal lug. “Stripping the cable jacket and crimping the terminal at the worksite naturally results in industrial waste. If we are able to do this process in advance off of worksite premises, then the waste generated from construction can be minimized,” Mr. Mizui evaluates.

The EF2 series is effective in establishing a worksite that nurtures the growth of workers. “In electrical construction there are many cases in which work cannot be done without the proper qualifications. Nonetheless there are many people who get frustrated by the menial tasks they must perform until receiving their qualifications. The EF2 plays an important role in creating an environment that allows the next generation of workers who are in the process of gaining their credentials to actively engage in the building and wire connection process,” says Mr. Mizui.

[In the future] Aiming towards there being no “tightening work” on site

Lastly Mr. Mizui speaks on his expectations for Hirose Electric. “In today’s home appliances there aren’t terminals. Image, voice and even control signals can be connected via one cable. Similarly, internally computers can have integrated connection via the use of connectors. If we could eliminate screw tightening from the electrical construction work, then production will increase. Furthermore we can build with higher quality and fewer workers. Everyone should be happy. I want HIROSE ELECTRIC to bring us one step closer to such an environment by using their unique perspective separate from that of the construction world to create novel ideas and apply them to the development of various products.”

(Interviewed in June, 2018)

Copyright© 2019 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

Hirose Electric Co., Ltd. and ZERO SCREW (TM) are trademarks or registered trademarks of Hirose Electric Co., Ltd. Other company names and product names are registered trademarks of respective companies. The position stated in the case example is at the time of interview.