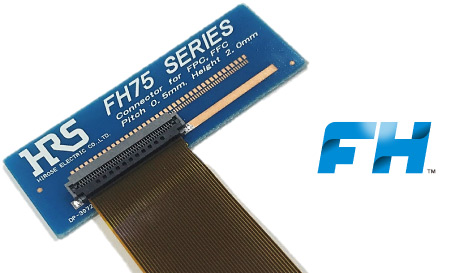

High Contact Reliability with Independent Two-Point Contact Design, 0.5mm Pitch, 125℃ Heat Resistance

FPC/FFC Connector FH75 Series for Automotive Applications

In recent years, many automobiles have been equipped with cameras, radars, LiDAR, and other devices to enable advanced driving support systems such as lane departure prevention and automatic emergency braking. These electronic devices are often placed in harsh environments such as near the engine room, which is subject to high temperatures and mechanical vibration. The connectors used in the devices must have high performance.

FH75 Series supports a high temperature of 125℃ due to the enhanced contact material and design. Also, high contact reliability is achieved with the high FPC/FFC retention force and two-point contact design. This FPC/FFC connector is ideal for automotive devices because it meets the severe test conditions of the industry and ensures high reliability in harsh environments.

Features

(1) High Contact Reliability

■ Independent Two-Point Contact Design

The two-point independent spring contact design reduces contact failure. For example, if a contact failure occurs due to dust intrusion on one contact, the other contact will not be affected and maintain a secure connection. This ensures high contact reliability.

■ FPC/FFC High Retention Force

FPC/FFC with tabs on both sides of the mated portion can be used with FH75. The tall-side catches securely holds the FPC/FFC tabs. Retention force is higher than the competitor’s products and it can be used safely even in an environment affected by vibration.

(2) Incomplete Mating Prevention

One of the causes of contact failure is incomplete mating of the FPC/FFC. The tabbed FPC/FFC used in FH75 allows visible inspection of the insertion status from the notched portion of the actuator to prevent incomplete mating, the cause of contact failure.

(3) Heat-resistant up to 125°C. Withstands Automotive Temperatures

The heat-resistant materials and spring used in the contact design minimize displacement due to heat and provides high contact reliability. As a result, FH75 can be used in a high-temperature environment of 125℃.

We have conducted strict tests required for automotive devices including temperature cycle tests (-55 to +125℃, 1,000 cycles) and heat resistance tests(125℃ for 1,000 hours) and verified that there are no problems.

| Item | Test Methods | Requirements | |

|---|---|---|---|

| Mechanical Characteristics |

Vibration | Frequency 10 to 55Hz, Half amplitude 0.75mm, 10 cycles in 3 axial directions. |

1. No electrical discontinuity, 1μs min. 2. Contact resistance 3. Appearance |

| Shock | 981m/s2, 6ms pulse duration 3 times in 3 axials and both directions. | ||

| Environmental Characteristics |

Temperature Cycle | Temperature -55→+15 to +35→+125→+15 to +35℃ Time 30→2 to 3→30→2-3 min. 1,000 cycles. |

1. Contact resistance 2. Insulation resistance 3. Appearance |

| Moisture Resistance | Exposed at 60±2℃, Relative humidity 90-95%, 1,000h. | ||

| Temperature Humidity Test | Exposed at -10 to +65℃, Relative humidity 90-96%, 10 cycles for 240h. | ||

| Dry Heat | Exposed at 125±2℃ for 1,000h. | ・接触抵抗 ・外観 |

|

| Cold | Exposed at -55±3℃ for 1,000h. | ||

| Corrosion Salt Mist | Exposed at 35±2℃, 5% Salt water spray for 96h. | ||

| Sulfur Dioxide (JIS C 60068-2-42) |

Exposed at 40±2℃, Relative humidity 80±5%, 25±5ppm. for 96h. | ||

| Hydrogen Sulfide (JIS C 60068-2-43) |

Exposed at 40±2℃, Relative humidity 80±5%, 10-15ppm. for 96h. | ||

Specifications

Characteristics

| Rated Current | Rated Voltage | Operating Temperature | Contact Resistance | Withstanding Voltage | Insulation Resistance | Mating Durability |

|---|---|---|---|---|---|---|

| 0.5A | 50V AC/DC | -40 to +125℃ | 50mΩ Max. *Includes FPC/FFC conductor resistance (L=8mm) | 150V AC for 1min. | 500MΩ Min. (100V DC) | 20 times |

- Supports MIPI D-PHY (1.5 Gbps)

- RoHS product

- No. of pos.: 40pos. 8, 10, 15, 30, 50, 60, 68, 80pos. (Planned for Development)

Applications

The FH75 Series, which provides high reliability through its high heat resistance and two-point contact design required for automobiles, can be used for LiDAR, automotive cameras, car navigation/audio systems, and other industrial equipment with a harsh operating environment.

Click here for other recommended connectors for autonomous driving.

In cases where the application will demand a high level of reliability, such as automotive, please contact a company representative for further information.