-

Category

-

I/O Connectors

List of useful search tools

List of useful search tools

-

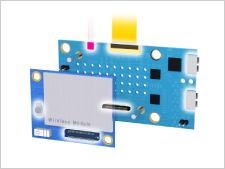

Standard Products

List of useful search tools

List of useful search tools

-

Wire-to-Board

List of useful search tools

List of useful search tools

-

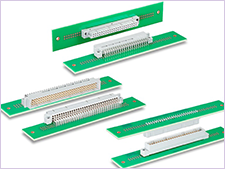

Board-to-Board, Board-to-FPC

-

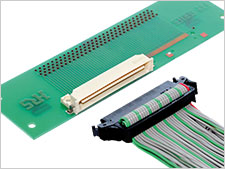

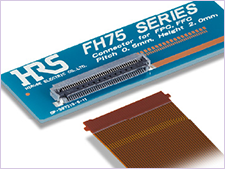

FPC/FFC Connectors

List of useful search tools

List of useful search tools

-

RF/Coaxial

List of useful search tools

List of useful search tools

-

Fiber Optic Connectors

List of useful search tools

List of useful search tools

-

Modular Connectors / Ethernet Connectors

List of useful search tools

List of useful search tools

-

Wire-to-Wire

List of useful search tools

List of useful search tools

-

IC Card/IC Socket

List of useful search tools

List of useful search tools

-

Card Edge Connectors

List of useful search tools

List of useful search tools

-

Automotive Connectors

List of useful search tools

List of useful search tools

-

Power Connectors

List of useful search tools

List of useful search tools

-

High Speed Connectors

List of useful search tools

List of useful search tools

-

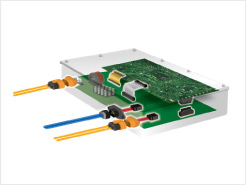

Sealed connector

List of useful search tools

List of useful search tools

-

I/O Connectors

-

Applications

- Consumer

-

Smartphone & Wearable

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Smart Appliances

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

PC & Tablet

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Other Consumer Equipment

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

- Automotive

-

Autonomous Car

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Powertrain (For Automotive)

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Infotainment (For Automotive)

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Connected Cars

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Automotive Lighting

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

- Industrial Machinery

-

Smart Grid

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Industrial Automation

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Robots

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Medical

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Telecommunications/Networking

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Data Centers

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Rail/Commercial Vehicles

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Other Industrial Equipment

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Office Automation

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

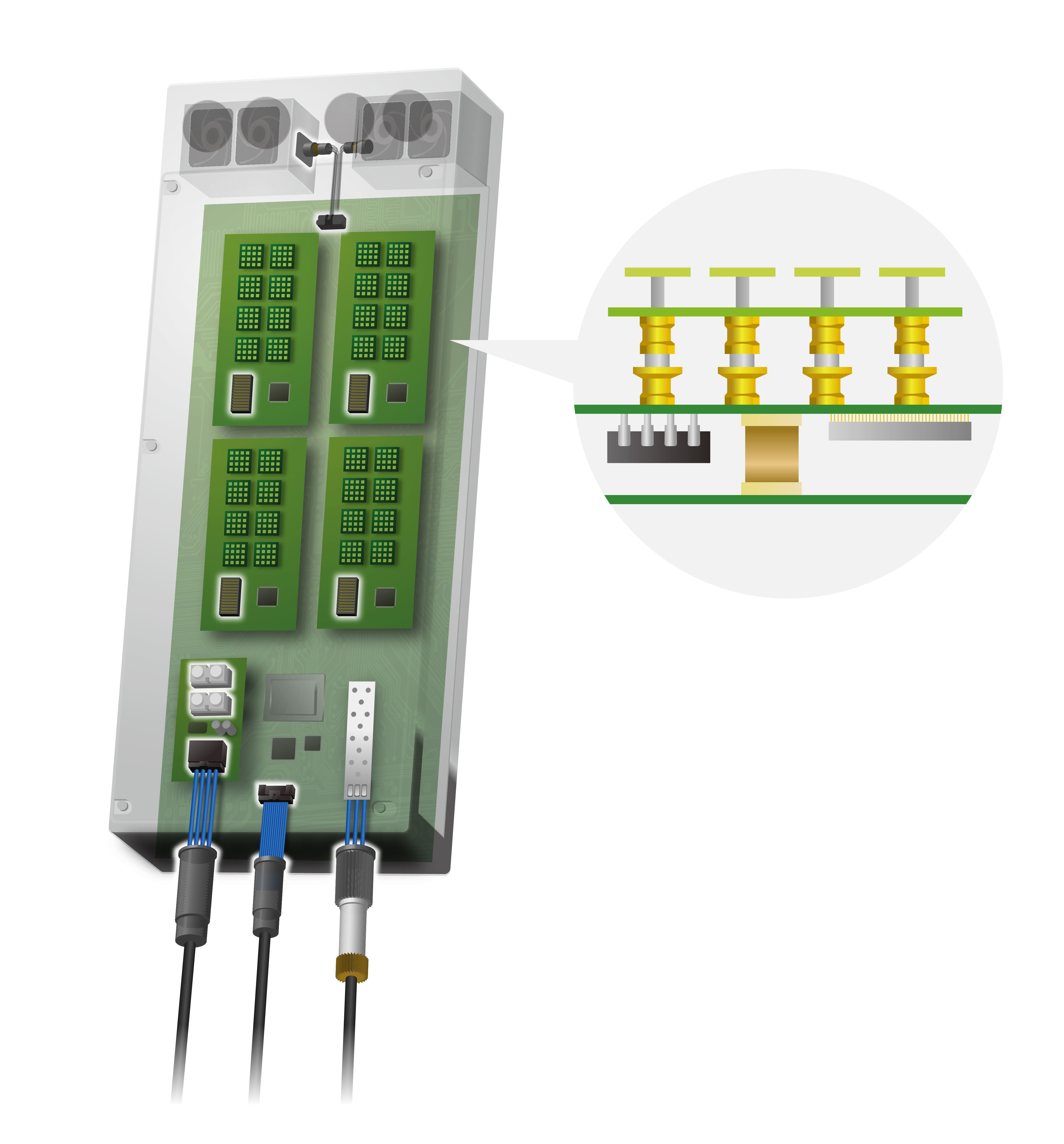

Introducing our company's quality assurance system, including testing facilities and evaluation systems, that support connector development and production.

Introduction video: First in Japan! ISO/IEC 17025 Testing facilities and evaluation system.

We are the first Japanese connector manufacturer to obtain ISO/IEC 17025 certification, an international certification system for testing and calibration laboratories (2004: Ichinoseki Testing Center, new building constructed in 2018). "ISO/IEC 17025" is a standard that certifies a laboratory's ability to produce accurate measurement results. Many countries around the world use "ISO/IEC 17025" as a standard for judging a laboratory's technical capabilities.

In addition, we opened the EMC laboratory (anechoic chamber and shielded rooms) and obtained "ISO/IEC 17025" certification (in 2018, at the headquarters of Hirose Electric Corporation). In the test, we use a correlation technology that makes the process of "Design, analysis and measurement" interrelated (actual measurement results can be predicted from analytical results). Our company has put in place a system in which these "Design, analysis and measurement" can be consolidated at a single site in order to simultaneously improve product quality and shorten development lead times.

Short Ver.

Long ver.