-

Category

-

I/O Connectors

List of useful search tools

List of useful search tools

-

Standard Products

List of useful search tools

List of useful search tools

-

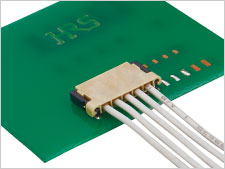

Wire-to-Board

List of useful search tools

List of useful search tools

-

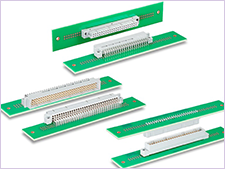

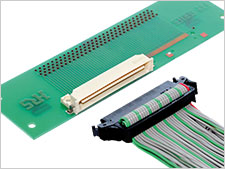

Board-to-Board, Board-to-FPC

-

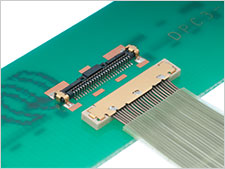

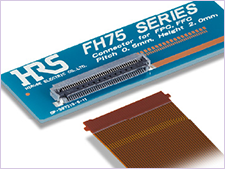

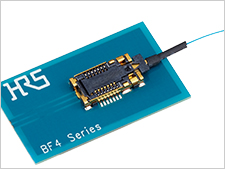

FPC/FFC Connectors

List of useful search tools

List of useful search tools

-

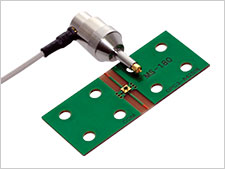

RF/Coaxial

List of useful search tools

List of useful search tools

-

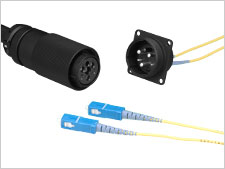

Fiber Optic Connectors

List of useful search tools

List of useful search tools

-

Modular Connectors / Ethernet Connectors

List of useful search tools

List of useful search tools

-

Wire-to-Wire

List of useful search tools

List of useful search tools

-

IC Card/IC Socket

List of useful search tools

List of useful search tools

-

Card Edge Connectors

List of useful search tools

List of useful search tools

-

Automotive Connectors

List of useful search tools

List of useful search tools

-

Power Connectors

List of useful search tools

List of useful search tools

-

High Speed Connectors

List of useful search tools

List of useful search tools

-

Sealed connector

List of useful search tools

List of useful search tools

-

I/O Connectors

-

Applications

- Consumer

-

Smartphone & Wearable

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Smart Appliances

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

PC & Tablet

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Other Consumer Equipment

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

- Automotive

-

Autonomous Car

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Powertrain (For Automotive)

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Infotainment (For Automotive)

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Connected Cars

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Automotive Lighting

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

- Industrial Machinery

-

Smart Grid

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Industrial Automation

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Robots

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Medical

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Telecommunications/Networking

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Data Centers

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Rail/Commercial Vehicles

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Other Industrial Equipment

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Office Automation

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

Useful for Increased Capacity, Advanced Functions, and Small Size Conversion of Automotive Battery

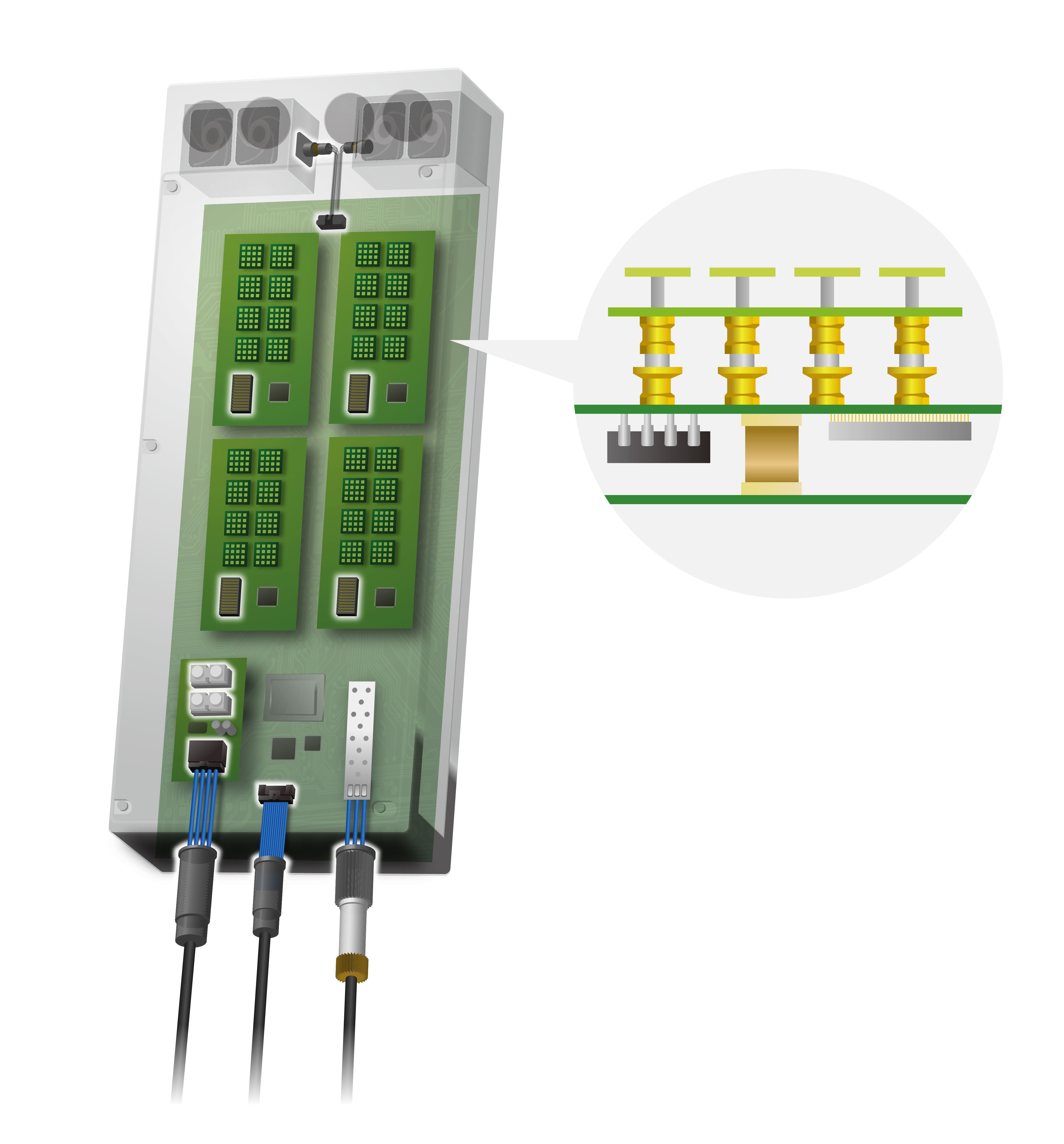

FPC Direct Connection Structure ZK1, TF70, TB4 Series

In order to extend the driving range of EVs (electric vehicles), battery capacity is increasing and advanced functions/small size are being introduced. The trend is changing from cable connection (discrete wire connection) to FPC/FFC connection.

To meet these needs, Hirose Electric began selling 3 types of FPC/FFC connectors in 2024. All of these connectors have an FPC direct connection structure and require little time to harness.

These FPC/FFC connectors are of automotive quality and feature high heat resistance performance, making them widely applicable to industrial equipment such as machine device and robots.

3 Comparison of Series's Main Specifications

| ZK1 Series | TF70 Series | TB4 Series | |

|---|---|---|---|

| Item Images |

|

|

|

| Features | High Hardness | Narrow Pitch, Vertical Variation | Low Back |

| Structure | FPC Direct Connection | FPC Direct Connection | FPC Direct Connection |

| Pitch | FPC Pitch=2mm×2 sheets Mounting Pitch=1mm |

0.5mm | 1mm |

| Height | 11mm | 6mm | 4.5mm |

| Depth | 25.1mm | 11mm | 12.5mm |

| Number of Positions |

Available : 32 Under Planning : 24, 40 |

Available : 50 Under Planning : 30 |

Available : 16, 30 Under Planning : 10, 22 |

| Vertical | ー | ✓ | ー |

| Operating Temperature |

-40 to 125℃ | -40 to 105℃ | -40 to 125℃ |

| Lock Strength (N) |

100 | 98.1 (10kgf) | 98.1 (10kgf) |

| Prying Force (Top) |

78N or more | ー | 60N or more |

| Vibration | LV214-S3, USCAR-V2 | ー | USCAR-V2 |

Features

Advantages of Replacing FPC-to-Board Connectivity (Simplified Assembly, Small Size/Light Weight Set)

The discrete wire method requires more man-hours to harness, as it requires soldering, Crimp, and insertion into each Contact. In addition, the weight increases in proportion to the number of cores.

On the other hand, FPC direct connection can be completed simply by inserting the FPC into the plug housing and attaching a retainer. There is little variation in quality, and features advantage is that it is light because it is FPC.

[Until Now] Discrete Wire System

・Harness process is complicated (Soldering, Crimp and Contact insertion)

・Crimp Contact and wires equal to the number of cores are required

・Weight increases in proportion to the number of cores (electric dose)

・space-saving for bending R of wires for routing is required

[From Now] FPC Direct Connection Structure

・Simply insert FPC and attach retainer

・Light

・Can be routed with Space-saving

High Contact Reliability

These FPC/FFC connectors (ZK1, TF70, TB4 Series) are designed with a wide effective engagement length to ensure contact reliability.

In addition, the ZK1 and TB4 Series have an independent Two-point Contact Design to help remove foreign objects during connection and maintain the connection if a foreign object is caught in one of the contacts.

(The structure of TB4 series is shown as an example.)

TF70 Series Offers a Choice of Right Angle or Straight Connections

With a narrow pitch of 0.5 mm, features TF70 series offers a choice of right angle or straight vertical variations. The FPC/FFC connectors allow flexibility in design because they can be selected according to application specifications.

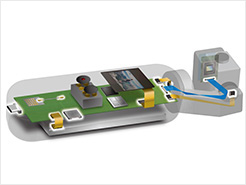

Use Cases, Key application/Applications

*In cases where the application will demand a high level of reliability, such as automotive, please contact a company representative for further information.

*The contents and specifications are subject to change.