-

Category

-

I/O Connectors

List of useful search tools

List of useful search tools

-

Standard Products

List of useful search tools

List of useful search tools

-

Wire-to-Board

List of useful search tools

List of useful search tools

-

Board-to-Board, Board-to-FPC

-

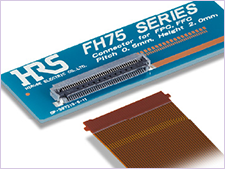

FPC/FFC Connectors

List of useful search tools

List of useful search tools

-

RF/Coaxial

List of useful search tools

List of useful search tools

-

Fiber Optic Connectors

List of useful search tools

List of useful search tools

-

Modular Connectors / Ethernet Connectors

List of useful search tools

List of useful search tools

-

Wire-to-Wire

List of useful search tools

List of useful search tools

-

IC Card/IC Socket

List of useful search tools

List of useful search tools

-

Card Edge Connectors

List of useful search tools

List of useful search tools

-

Automotive Connectors

List of useful search tools

List of useful search tools

-

Power Connectors

List of useful search tools

List of useful search tools

-

High Speed Connectors

List of useful search tools

List of useful search tools

-

Sealed connector

List of useful search tools

List of useful search tools

-

I/O Connectors

-

Applications

- Consumer

-

Smartphone & Wearable

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Smart Appliances

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

PC & Tablet

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Other Consumer Equipment

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

- Automotive

-

Autonomous Car

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Powertrain (For Automotive)

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Infotainment (For Automotive)

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Connected Cars

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Automotive Lighting

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

- Industrial Machinery

-

Smart Grid

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Industrial Automation

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Robots

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Medical

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Telecommunications/Networking

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Data Centers

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Rail/Commercial Vehicles

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Other Industrial Equipment

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Office Automation

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

QR/P18 Series Scheduled to be discontinued

High-Pin-Count Rectangular Rack/Panel ID Connectors

Features

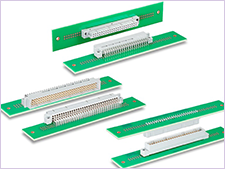

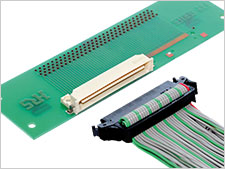

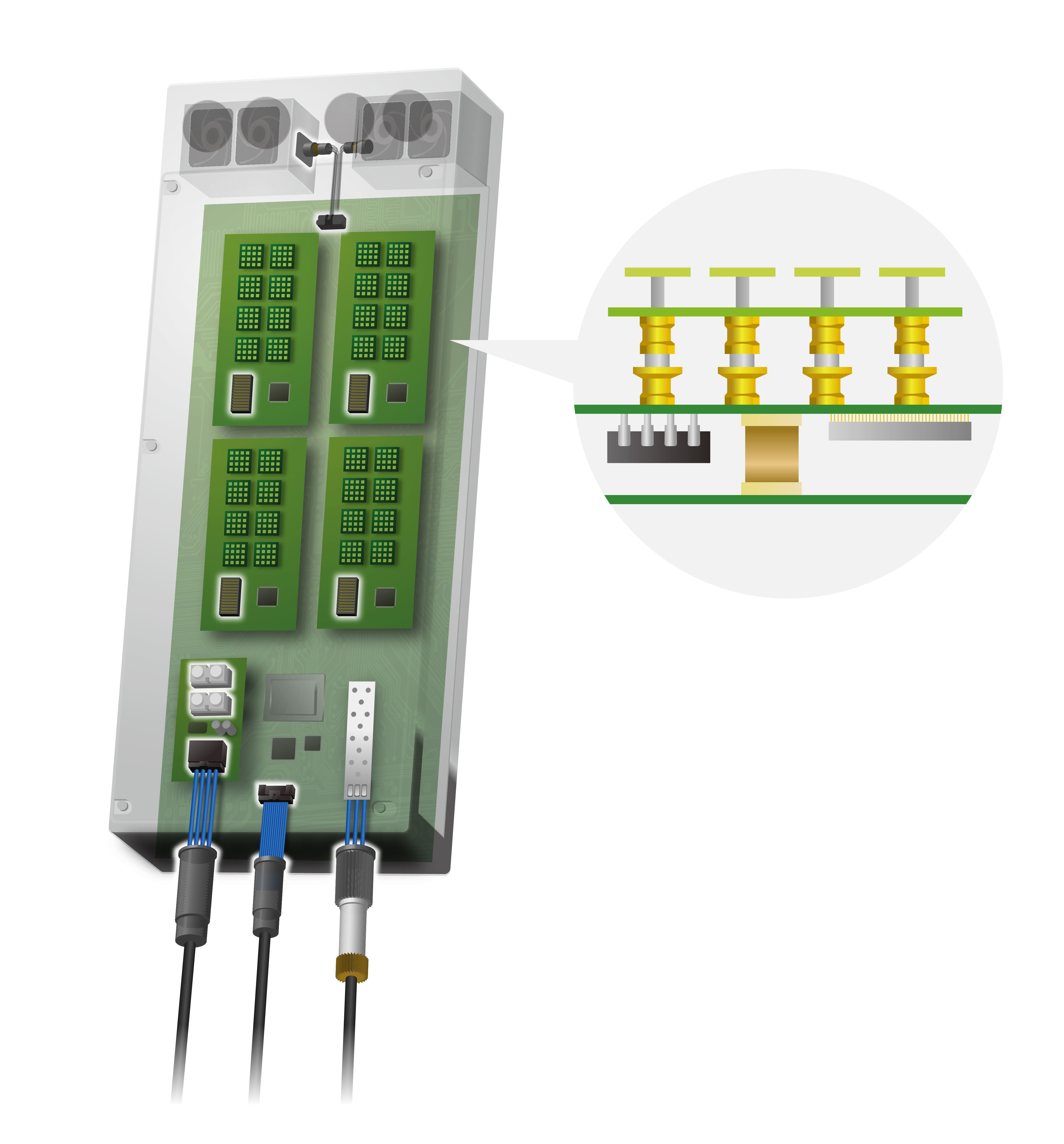

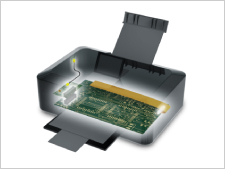

Rectangular, High-Pin-Count Rack/Panel Insulation Displacement Connectors (IDC)

The QR/P18 Series of miniature rack/panel connectors is designed for the complete segmentation of the structure of the external holder/terminal units of the well-received QR/P Series of plug-in rectangular rack/ panel connectors; furthermore, the subsequent insertion of the harnessed terminal unit affords a more efficient harness mounting task. These connectors are configured with 12, 18, or 24 pos.(IDC) in the signal line, and 4 pos.(crimp) in the power line.

1. Completely separated structure of the external holder/terminal unit

In order to improve the harness procedures, the connectors are designed for the complete segmentation of the external holder and the signal/ power supply unit, and inserting the harnessed contacts aims to improve the workability of the power supply/signal line harness as well as the mounting to the set.

2. Signal unit

The signal unit uses the highly reliable insulation displacement connection method. (The wire is AWG #26 and the insulation outter diameter is 0.88mm.) The insulation displacement procedure can now be used by attaching a special applicator to a commercially available automatic insulation displacement machine, or a manual press tool can also be selected.

3. Power supply

The power supply terminals permit the use of a crimp harness using wire of AWG#16 to 18 (and insulation outside diameter of 2.1 to 2.2mm), and can accommodate a maximum of 12 A.

4. Sequential mating structure

Two sequential contacts in the signal male unit and one sequential contact in the power supply female unit are provided for safety operation.

5. Panel installation

Installation to a panel uses a single-action method on the anchored side and a floating screw structure on the floating side which permits smooth insertion and disconnection without forcing.

- Connector Type

- Contact

- Parts

- Panel Mounting Style

- Cable Assembly

- No

- Cable Length

- Generic Type

- Industry Standard

- Safety Standards

- Performance Characteristics

- Transmission Rate

- Water Resistance

- Salt Spray Test Duration (Corrosion Resistance)

- 48 hours h

- Mating/Unmating Cycles

- 3000

- Number of Positions

- Remarks on Number of Positions

- Contact Pitch

- Contact Plating

- Gold

- Locking Style

- Rated Current

- 12.0 A

- Rated Current other

- Rated Voltage (AC)

- AC 300.0 V

- Rated Voltage (AC) other

- Rated Voltage (DC)

- DC 300.0 V

- Rated Voltage (DC) other

- Mounting Style

- Connector Orientation

- Mounting Side

- Wire Termination Method

- Crimping

- Recommended Min. Wire Size (AWG)

- 18

- Recommended Max. Wire Size (AWG)

- 16

- Recommended Min. Wire Size (mm²)

- Recommended Max. Wire Size (mm²)

- Operating Temperature Max.

- 105 ℃

- Operating Temperature Min.

- -55 ℃

- Mounting direction

- Floating Range(XY)(mm)

- Effective Mating Length(Z)(mm)

- Cable Color

- Connector Type Details

List of Connectors (Specification Sheet, 2D drawings, 3D models, Distributor inventory)

Document

In cases where the application will demand a high level of reliability, such as automotive, please contact a company representative for further information.