-

Category

-

I/O Connectors

List of useful search tools

List of useful search tools

-

Standard Products

List of useful search tools

List of useful search tools

-

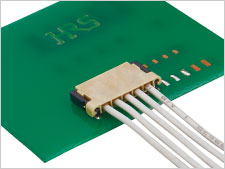

Wire-to-Board

List of useful search tools

List of useful search tools

-

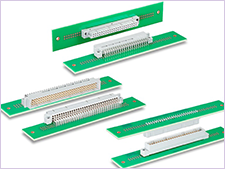

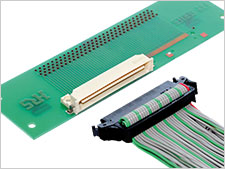

Board-to-Board, Board-to-FPC

-

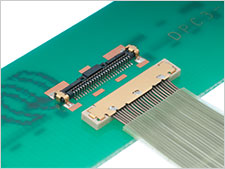

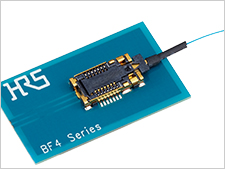

FPC/FFC Connectors

List of useful search tools

List of useful search tools

-

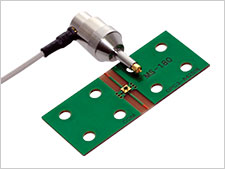

RF/Coaxial

List of useful search tools

List of useful search tools

-

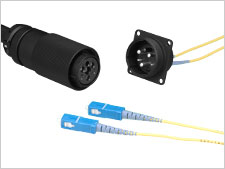

Fiber Optic Connectors

List of useful search tools

List of useful search tools

-

Modular Connectors / Ethernet Connectors

List of useful search tools

List of useful search tools

-

Wire-to-Wire

List of useful search tools

List of useful search tools

-

IC Card/IC Socket

List of useful search tools

List of useful search tools

-

Card Edge Connectors

List of useful search tools

List of useful search tools

-

Automotive Connectors

List of useful search tools

List of useful search tools

-

Power Connectors

List of useful search tools

List of useful search tools

-

High Speed Connectors

List of useful search tools

List of useful search tools

-

Sealed connector

List of useful search tools

List of useful search tools

-

I/O Connectors

-

Applications

- Consumer

-

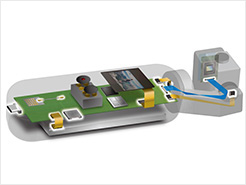

Smartphone & Wearable

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Smart Appliances

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

PC & Tablet

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Other Consumer Equipment

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

- Automotive

-

Autonomous Car

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Powertrain (For Automotive)

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Infotainment (For Automotive)

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Connected Cars

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Automotive Lighting

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

- Industrial Machinery

-

Smart Grid

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Industrial Automation

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Robots

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Medical

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Telecommunications/Networking

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Data Centers

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Rail/Commercial Vehicles

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Other Industrial Equipment

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

-

Office Automation

Recently Reviewed Application

Recently Reviewed Application

Recommended Applications

Recommended Applications

What is a connector? Hirose Electric, a long-established connector manufacturer, answers the simple questions like "What is a connector?” and provides more technical information including important points for mounted products in our Connector Basics You’ll Want to Know Series.

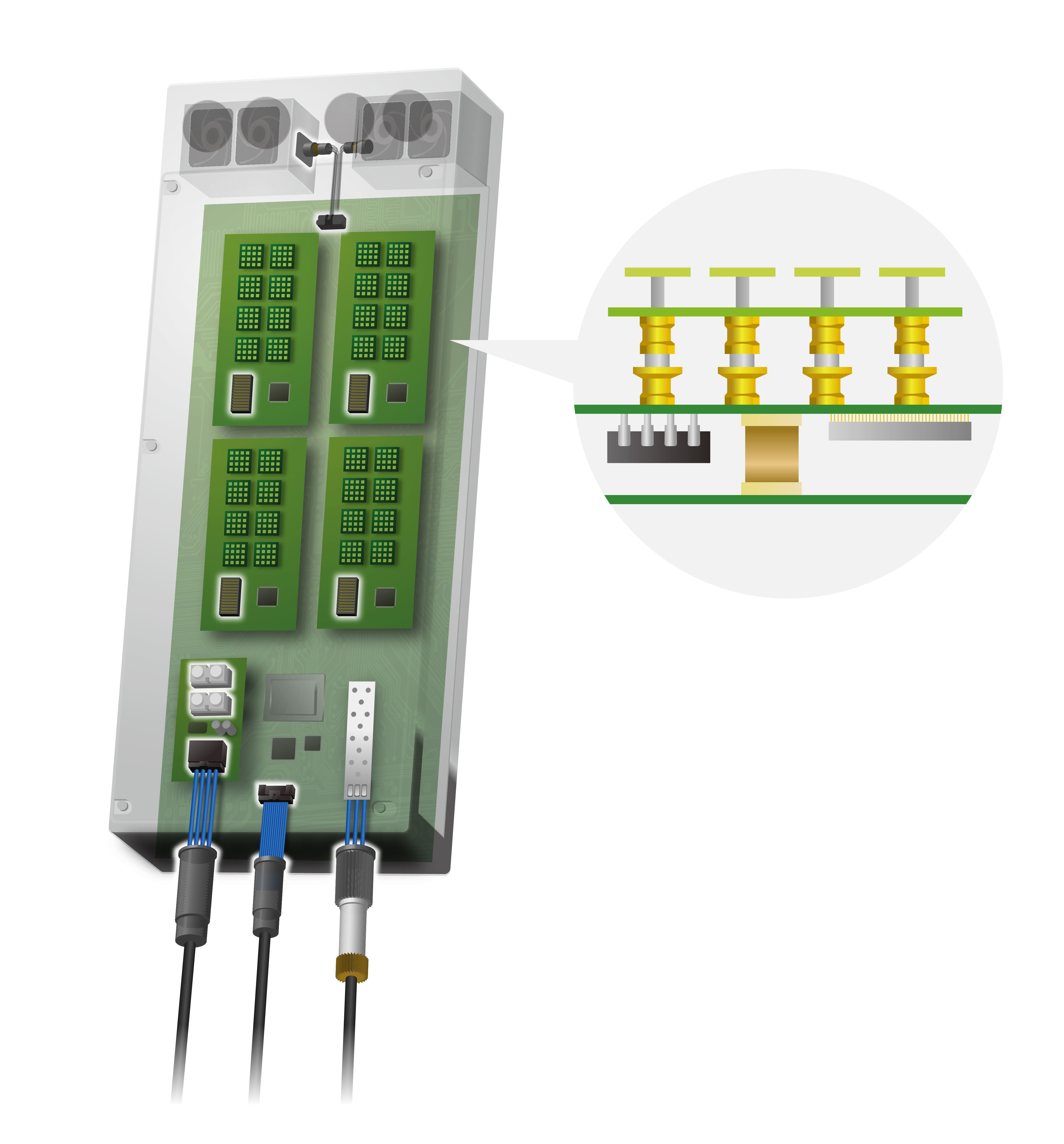

In this third article titled “Key Interconnection Points for Connectors: Board Mounting”, we discuss the second of the three key connection points for the correct transmission of electricity. There are two main methods of board mounting: through hole technology and SMT soldering. Let's take a look at the differences and features of each.

Through Hole Technology (THT)

THT is a method of board mounting in which contact leads are inserted into holes (through-holes) drilled in the board and dipped into melted solder on the back side.

The THT method can be used for single-sided, double-sided and multi-layered boards and is widely used due to this versatility.

Insert the contact leads into the holes on the board and solder to the opposite side.

The features of THT are as follows:

・The connection area between the board and the connector is large, which increases the strength of the bonds.

・Various components of different sizes can be mounted at once.

・Since it is difficult to adjust the amount of solder, contacts close together may be inadvertently connected, causing a short circuit (Solder Bridge).

・Through holes occupy space on both sides of the board.

SMT Soldering (Reflow Soldering, Surface Mounting)

SMT soldering (reflow soldering, surface mounting) is a method of attaching components to PCBs by applying cream solder to a PCB pattern, which is then heated using a reflow machine to melt the solder and form solder joints.

The connector contacts must maintain their coplanarity before heating, during heating in the reflow equipment, and after heating until cooled down and the solder hardens. If the contact coplanarity cannot be maintained until the solder hardens, the solder will remain unattached.

The connection area to the board is smaller than that of through hole mounting, making it suitable for mounting of small components. For this reason, this mounting method is frequently used for mobile devices such as smartphones.

The features of SMT soldering include the following:

・The back side of the board can be used effectively because components are only attached to the front board surface.

・Solder bridges are less likely to occur, making it ideal for narrow pitch components. It is the standard mounting method for mobile devices.

・Since components are only secured to the front board surface, the retention force is weaker than through hole mounting.

There are other board mounting methods such as press-fit, but we have introduced the main two methods here. The next article focus on the contact portion including connector mating and contact resistance stability.