-

製品カテゴリ

- I/O

- 規格品

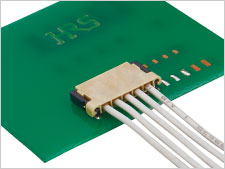

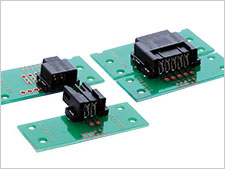

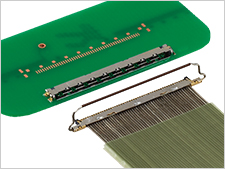

- 基板対ケーブル

-

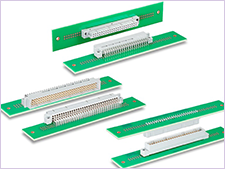

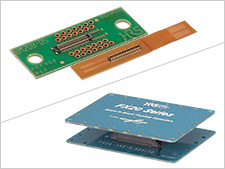

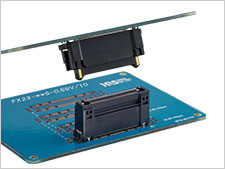

基板対基板/基板対FPC

便利な検索ツール 一覧

便利な検索ツール 一覧

種類別セレクトマップ

種類別セレクトマップ

-

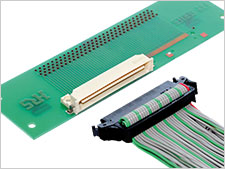

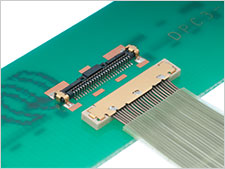

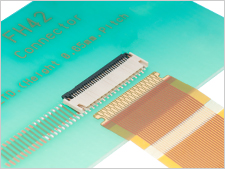

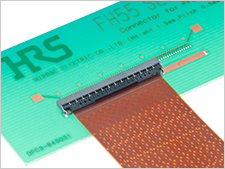

FPC/FFC

便利な検索ツール 一覧

便利な検索ツール 一覧

種類別セレクトマップ

種類別セレクトマップ

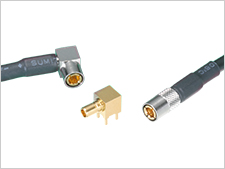

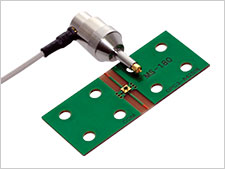

- 高周波同軸コネクタ

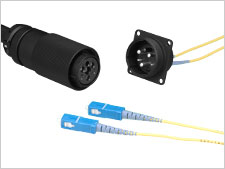

- 光コネクタ

- モジュラージャック/プラグ

- 中継コネクタ

- カードコネクタ/ICソケット

- カードエッジコネクタ

- 自動車用コネクタ

- 電源用コネクタ

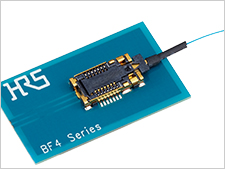

- 高速伝送対応コネクタ

- 防水コネクタ

-

用途・アプリケーション

- コンシューマ

-

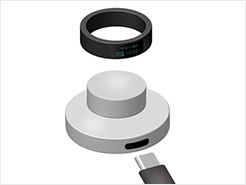

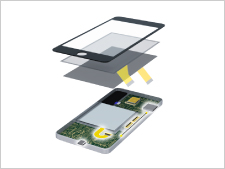

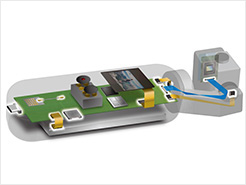

スマートフォン&ウェアラブル

最近見たアプリケーション

最近見たアプリケーション

おすすめのアプリケーション

おすすめのアプリケーション

-

スマート家電

最近見たアプリケーション

最近見たアプリケーション

おすすめのアプリケーション

おすすめのアプリケーション

-

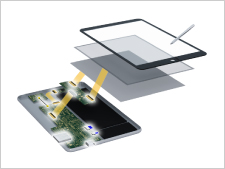

PC&タブレット

最近見たアプリケーション

最近見たアプリケーション

おすすめのアプリケーション

おすすめのアプリケーション

-

その他コンシューマ

最近見たアプリケーション

最近見たアプリケーション

おすすめのアプリケーション

おすすめのアプリケーション

- 自動車

-

自動運転車

最近見たアプリケーション

最近見たアプリケーション

おすすめのアプリケーション

おすすめのアプリケーション

-

車載用パワートレイン

最近見たアプリケーション

最近見たアプリケーション

おすすめのアプリケーション

おすすめのアプリケーション

-

車載用インフォテインメント

最近見たアプリケーション

最近見たアプリケーション

おすすめのアプリケーション

おすすめのアプリケーション

-

コネクテッドカー

最近見たアプリケーション

最近見たアプリケーション

おすすめのアプリケーション

おすすめのアプリケーション

-

車載ライティング

最近見たアプリケーション

最近見たアプリケーション

おすすめのアプリケーション

おすすめのアプリケーション

- 産機

-

スマートグリッド

最近見たアプリケーション

最近見たアプリケーション

おすすめのアプリケーション

おすすめのアプリケーション

-

ファクトリーオートメーション

最近見たアプリケーション

最近見たアプリケーション

おすすめのアプリケーション

おすすめのアプリケーション

-

ロボット

最近見たアプリケーション

最近見たアプリケーション

おすすめのアプリケーション

おすすめのアプリケーション

-

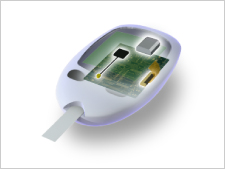

医療機器

最近見たアプリケーション

最近見たアプリケーション

おすすめのアプリケーション

おすすめのアプリケーション

-

テレコム/ネットワーク

最近見たアプリケーション

最近見たアプリケーション

おすすめのアプリケーション

おすすめのアプリケーション

-

データセンター

最近見たアプリケーション

最近見たアプリケーション

おすすめのアプリケーション

おすすめのアプリケーション

-

鉄道・建機

最近見たアプリケーション

最近見たアプリケーション

おすすめのアプリケーション

おすすめのアプリケーション

-

その他産業用機器

最近見たアプリケーション

最近見たアプリケーション

おすすめのアプリケーション

おすすめのアプリケーション

-

OA機器

最近見たアプリケーション

最近見たアプリケーション

おすすめのアプリケーション

おすすめのアプリケーション